HUATE-2015/2518/3026/4026/5026/4032/5032/6032/8032/5040/6040/8040

Product Features

Beam

The stepped L-shaped design enhances rigidity, while the recessed C-shaped structure provides superior bending resistance

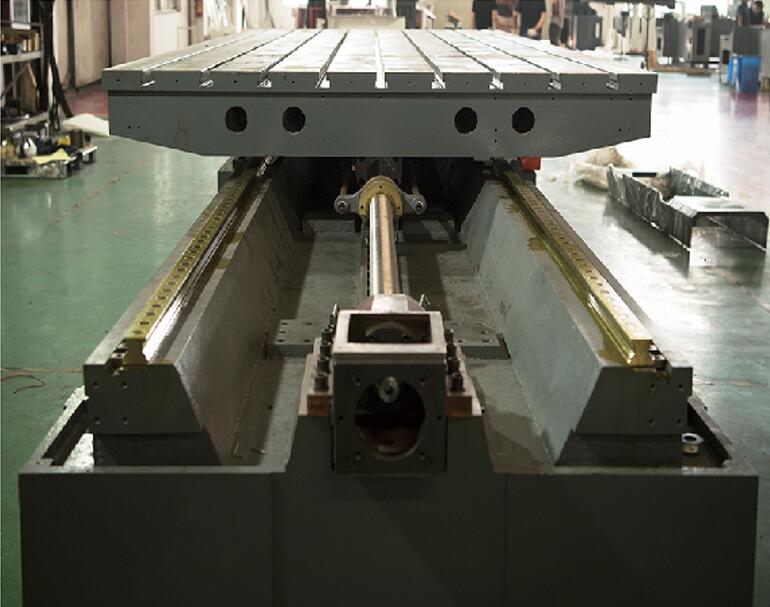

Base

The machine incorporates an oversized 'T.-shaped double-layer box base, meticulous-ly scraped at each joint to ensure exceptional stability and durability. It utilizes larger screws and linear rails compared to similar models, ensuring high rigidity and overall stability. The integrated built-in oil-water separation and eyebrow row structure promote environmental friend ness and cost savings for the entire machine.

Column

The machine features a closed "back" type double-layer casting structure, construct-ed from high-quality Meehanite standard cast iron. It undergoes dual electric furnace aging to ensure long-term seismic resistance and prevent deformation. Additionally, at least 80% of the column range aligns with the guide rail, ensuring that the linear rail support is equivalent to that of a hard rail support.

| HT-2015 | HT-2518 | HT-3026 | HT-4026 | HT-5026 | HT-4032 | ||

| Machining range |

|||||||

| X-axis travel | mm | 2000 | 2500 | 3000 | 4000 | 5000 | 4000 |

| Y-axis travel | mm | 1500 | 1800 | 1800 | 2600 | 2600 | 3200 |

| Z-axis travel | mm | 800 | 800 | 1000 | 1000 | 1000 | 1000 |

| Effective Width of Gantry | mm | 1600 | 1800 | 2600 | 2600 | 2600 | 3200 |

| Spindle to worktable distance | mm | 200-1000 | 200-1000 | 200-1200 | 200-1200 | 200-1200 | 200-1200 |

| Worktable | |||||||

| Worktable Size | mm | 2000*1300 | 2500*1600 | 3000*2100 | 4000*2100 | 5000*2100 | 4000*2500 |

| Worktable Load Capacity | kg | 6000 | 10000 | 12000 | 15000 | 17000 | 20000 |

| T-slot(Width*Spacing) | mm | 22*180 | 22*180 | 28*220 | 28*220 | 28*220 | 28*220 |

| Spindle | |||||||

| Spindle Drive Method | Belt | Belt | Belt | Belt | Belt | Belt | |

| Spindle Speed | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Spindle Power | kw | 18.5-22 | 15-22 | 15-22 | 15-22 | 15-22 | 15-22 |

| Spindle Torque | N.m | 143 | 249-442 | 249-442 | 249-442 | 249-442 | 249-442 |

| Spindle Taper/Pull Stud | BT50/45° | BT50/45° | BT50/45° | BT50/45° | BT50/45° | BT50/45° | |

| Drive Feed |

|||||||

| Rapid Displacement X/Y/Z | m/min | 12/10/10 | 12/10/10 | 12/10/10 | 12/10/10 | 12/10/10 | 8/10/10 |

| Max Chip Removal Speed X/Y/Z | m/min | 8 | 8 | 8 | 8 | 8 | 6 |

| Minimum Resolution | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Accuracy | |||||||

| Positioning X/Y/Z | mm | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repeatability X/Y/Z | mm | ±0.004/300 | ±0.004/300 | ±0.004/300 | ±0.004/300 | ±0.004/300 | ±0.004/300 |

| Others | |||||||

| Guide Rail Specification | mm | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail |

| Screw Rod Specification | mm | 63/50/50 | 80/63/50 | 80/63/50 | 80/63/50 | 80/63/50 | 80/63/50 |

| Servo Motor Power X/Y/Z | kw | 3/3/3 | 6/7/7 | 6/7/7 | 9/7/7 | 9/7/7 | 9/7/7 |

| Power Requirement | kw | 40 | 40 | 40 | 60 | 60 | 60 |

| Machine Tool Size | mm | 7700 6000 4700 |

8900 6000 4700 |

9900 6500 5000 |

11900 6500 5000 |

13000 6500 5000 |

11900 7550 5200 |

| Approximate Machine Weight | t | 19 | 23 | 34 | 42 | 46 | 45 |

| HT-5032 | HT-6032 | HT-8032 | HT-5040 | HT-6040 | HT-8040 | ||

| Machining range | |||||||

| X-axis travel | mm | 5000 | 6000 | 8000 | 5000 | 6000 | 8000 |

| Y-axis travel | mm | 3200 | 3200 | 3200 | 4000 | 4000 | 4000 |

| Z-axis travel | mm | 1000 | 800 | 1000 | 1000 | 1000 | 1000 |

| Effective Width of Gantry | mm | 3200 | 3200 | 3200 | 4000 | 4000 | 4000 |

| Spindle to worktable distance | mm | 200-1200 | 200-1200 | 200-1200 | 200-1200 | 200-1200 | 200-1200 |

| Worktable | |||||||

| Worktable Size | mm | 5000*2500 | 6000*2500 | 8000*2100 | 5000*3100 | 6000*3100 | 8000*3100 |

| Worktable Load Capacity | kg | 25000 | 25000 | 30000 | 25000 | 25000 | 30000 |

| T-slot(Width*Spacing) | mm | 28*220 | 28*220 | 28*220 | 28*220 | 28*220 | 28*220 |

| Spindle | |||||||

| Spindle Drive Method | Belt | Belt | Belt | Belt | Belt | Belt | |

| Spindle Speed | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Spindle Power | kw | 15-22 | 15-22 | 15-22 | 15-22 | 15-22 | 15-22 |

| Spindle Torque | N.m | 249-442 | 249-442 | 249-442 | 249-442 | 249-442 | 249-442 |

| Spindle Taper/Pull Stud | BT50/45° | BT50/45° | BT50/45° | BT50/45° | BT50/45° | BT50/45° | |

| Drive Feed | |||||||

| Rapid Displacement X/Y/Z | m/min | 8/10/10 | 8/10/10 | 8/10/10 | 8/10/10 | 8/10/10 | 8/10/10 |

| Max Chip Removal Speed X/Y/Z | m/min | 6 | 6 | 6 | 6 | 6 | 6 |

| Minimum Resolution | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Accuracy | |||||||

| Positioning X/Y/Z | mm | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repeatability X/Y/Z | mm | ±0.004/300 | ±0.004/300 | ±0.004/300 | ±0.004/300 | ±0.004/300 | ±0.004/300 |

| Others | |||||||

| Guide Rail Specification | mm | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail | 55/55/ZAxis hard rail |

| Screw Rod Specification | mm | 80/63/50 | 80/63/50 | 80/63/50 | 80/63/50 | 80/63/50 | 80/63/50 |

| Servo Motor Power X/Y/Z | kw | 9/7/7 | 9/7/7 | 9/7/7 | 9/7/7 | 9/7/7 | 9/7/7 |

| Power Requirement | kw | 60 | 60 | 60 | 60 | 60 | 60 |

| Machine Tool Size | mm | 15650 7550 5200 |

16650 7550 5200 |

19550 7500 5200 |

15650 7550 5200 |

16650 7550 5200 |

19550 7550 5200 |

| Approximate Machine Weight | t | 60 | 64 | 78 | 62 | 66 | 80 |

*Note: Our company's products are constantly improving. If there are any changes to the above information, no further notice will be given, and the technical documents shall prevail.

Standard configuration:

1. CNC system FANUC Oi MF (1)

2. Spindle constant temperature cooling system

3. Z-axis hydraulic balance system

4. Pneumatic, hydraulic, and centralized lubrication systems

5. Tool cooling system

6. Screw track chip conveyor

7. Tri color lamps and lighting fixtures

8. Automatic power-off device

9. Standard attachments and related documents

10. Common maintenance tools

Option configuration:

1. Spindle direct connection 10000 revolutions per minute (Setco)

2. BF gearbox (1:4)

3. Z-axis track

4.24/32/40/60 knife magazine

5. Water outlet from the spindle center

6. Side milling head (manual/semi-automatic/fully automatic)

7. Each axis grating ruler

8. Workpiece probe

9. Tool presetter